Is that a calibration of gas detectors, when, and how it works?

Gas detectors or gas detection devices are crucial to use in industries and working environments that are potentially exposed to dangerous gases. However, to make sure that it works properly and provide an accurate result, the calibration process needs to be done regularly. In this article, we'll discuss in more detail what it is. calibration gas detector And the steps that need to be made in calibration. By understanding the proper gas detector calibration, you can ensure security and health at work or in your neighborhood that requires the use of this device.

What's a gas detector?

Gas detector is a tool used to detect the presence of dangerous gases in the surrounding environment. It's usually used in industry, chemical companies, mining and other sectors that require security scrutiny to avoid the exposure of employees or jobs on dangerous gases that could harm health.

Gas detector has some kind, including a type of single gas measurement and a multigas gas gas. The size of a single gas is used to measure the concentration of a single gas in the air, while measuring a multigas gas gas can measure some type of gas in one tool.

The detector's gas works by detecting dangerous gases through sensors attached to them. The sensor will then send a signal to a measuring device and show the results on the screen or any other device.

The use of gas detectors is very important in maintaining security and health workers in a working environment that is potentially exposed to dangerous gases. With the gas detector, the workers can take proper precautions if possible to detect harmful gases in the surrounding environment.

What's a gas detector?

The calibration of a gas detector is a process that is done to ensure that a gas gauge or a gas detector can display an accurate and reliable value while detecting the presence of a gas in an environment. It's important to do regular calibration because uncalibrated gas detectors can provide inaccurate results, which can cause serious accidents or dangers.

What's the benefit of the gas detector calibration?

The benefit of the gas detector calibration is as follows:

- Ensuring the precision of the reading: the calibration of the gas detector helps ensure that the readings given by the gas detector are accurate and reliable. In situations where reading errors can take a serious impact on safety, such as in a working environment where toxic or flammable gases present, regular calibration is very important.

- The proper maintenance: the calibration of the Gas Detector is an important part of the proper maintenance to ensure the detector is functioning properly. It helps to extend the life of a gas detector and minimize the possibility of error and detection failure.

- Maintain safety standards: calibration gas detector helps ensure gas detectors meet safety standards required by regulatory agencies and industries. It's especially important in an industrial environment, where the safety of workers can be threatened if the gas detector doesn't function properly.

- Avoiding additional costs: Regular gas detector calibration helps minimize additional costs due to repair or replacement damaged or inaccurate gas detectors. By regular calibration, read errors can be detected earlier and detectors can be fixed before it becomes irreparable.

In general, the calibration of gas detectors is crucial in ensuring the safety of the environmental work and industry. It helps to minimize possible read errors and make sure the gas detectors function correctly and effectively.

When does a gas detector have to be calibrated?

Gas detectors must be calibrated regularly to ensure that the device functions properly and provides accurate results. Some factors that affect calibration frequencies among other types of gas are detected, frequency of use, and environmental conditions where the device is used.

In general, gas detectors need to be calibrated at least once in six months or according to the manufacturer's recommendation. However, there are some factors that can affect calibration frequencies, such as:

- Hard environment or environment where tools are used often exposed to dangerous gases

- Number of tool usage and usage frequencies

- intensive tool usage

- Date expired. Gas detector sensor

Besides, if there's a malfunction in the device or if the gas detector measurement is not consistent with the expected results, it needs recalibration to make sure the device functions correctly.

The calibration of gas detectors must also be used whenever sensors or critical parts of tools are replaced, such as gas sensors or batteries. In this case, calibration needs to be done to adjust the measurement results to the installed new sensors.

How do you calibrate a gas detector?

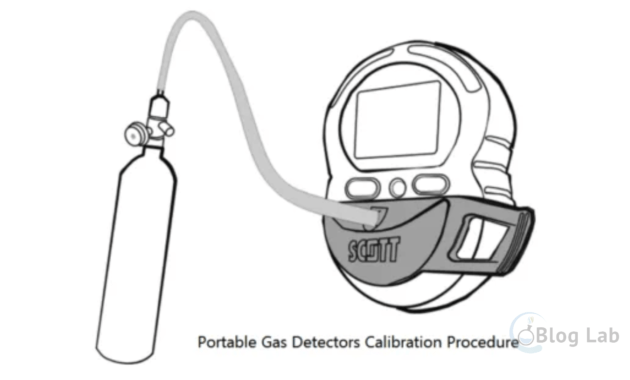

The way a gas detector calibration can vary depends on the type of gas gauge used. However, here I'm going to give you one example to calibrate the gas detector from one of the devices, which is portable gas detectors, and this is the steps:

Procedure for portable gas detector calibration

According to US / NZS standard 60079,29.2: 2008 about the gas detectors - elections, installations, usage, and maintenance detectors for flammable gases and oxygen, a portable gas monitor must be set up regularly by a competent person according to the factory instructions.

Over time, the monitor / gas detector could lose its sensitivity due to aging, high concentration gas exposure, sensor poisoning, etc., so the precision of the gas monitor must be verified regularly. It can be done by calibrating to make sure the gas monitors operate properly.

Calibration frequency

The best calibration frequencies must be determined by local standards, corporate policy, and industry's best practices. Adjusting calibration frequency must be adjusted to a risk-related level. High-risk situations require higher calibration frequencies than low risk situations. The best practice is to test the gas monitors with the known concentration of gas before they're used.

Another way to determine the calibration frequency is to check the gas monitor response every day in the previously defined atmosphere (for example for 10 days). If nothing causes the loss of sensitivity to the sensors installed in that atmosphere, then the tests show that there's no need to adjust anything and the time between checks can be extended.

Calibration Procedure

The calibration procedure consists of zero calibration and sensor calibration with a known concentration of gas.

- Zero calibration is done to establish the basic atmospheric readings and free from toxic gas and flammable.

- Initial readings must show zero value for carbon monoxide, hydrogen sulfide, flammable materials, and 20.9% for oxygen.

- Calibration range is done to adjust the gas monitor response to suit the known concentration of gas.

- Sensors can lose sensitivity through normal degradation, exposure to high concentration of gas, or sensor poisoning.

- Meanwhile, the Span calibration was done to ensure that the gas monitors were able to detect gas targets with accuracy in specific operating parameters.

To calibrate the range manually, some of the equipment needed among others:

- The calibration of gas with appropriate concentration, such as:

- 50 ppm CO

- 25 ppm H2S

- 1.62 Vol% CH4 (32% LEL)

- 19 Vol% O2

- Tygon tube to connect the gas calibration with a gas monitor that will be calibrated.

- The gas flow regulator that provides 0.5 LPM gas flow rates.

- The calibration adapter that serves as the mediator between the gas calibration tube and the gas monitor.

Zero / Zero calibration procedure (also known as fresh air calibration) can be performed at the following steps:

- Make sure the air around the gas monitor is free of toxic gas or flammable. If you can't confirm air hygiene, use the Zero Air gas tube.

- Turn on the gas monitor device.

- Press and hold Right Operating Keys until the "Please Wait" display.

- The zero calibration process will begin.

- If the display shows "Is Air Clear," make sure the air hygiene and press Right Operating Keys to start a zero calibration.

- Wait until the device finishes the zero calibration process.

- If zero calibration succeeds, LCD will display "APPLY GAS" as a sign that the device is ready to calibrate the range.

SPAN calibration procedure

Before starting the calibration process, it's important to check whether the concentration of calibration gas is tuned to a Provingé device according to the actual concentration of gas in the gas tube.

When "APPLY GAS" is shown:

- Set the flow regulator to the gas tube and verify the pressure tube.

- Connect Tygon tube to regulator and calibration adapter.

- If the password screen appears, enter a 4-digit password using the left operating button to scroll numeric characters and the right operation key to receive entries.

- Install calibration adapters to the gas monitors and use the gas from the regulator.

- Once each sensor is calibrated, the device displays "CAL PASSED" then "REMOVE GAS."

- Release the Calibration Adaptor and wait for the main display of the device to return before shutting down the device.

Note:

The calibration principle is almost the same for all brands / models, depending on the gas detector models, the display button / text will vary.

Where's the calibration service gas detector?

Gas detector calibration is available in various places, such as calibration labs, gas detection stores, tool care providers, and gas detection producers. Some companies provide a direct calibration service at your location, depending on the type of tools and calibration needs. You can look for more information about gas detector calibration by connecting services in your area. Be sure to select a trusted service provider and have experience in calibrating gas detection tools to ensure consistent calibration results. And here we're going to recommend a place that provides a gas detector calibration service for those of you who are confused looking for it, which is a company called PT Envilife in Indonesia, to know the full information about the calibration of gas detectors. Please visit this link at www.envical.co.id.

Now that's a conversation that admin can talk to you about what the gas detector calibration is that you can learn in the article above, hopefully the article I wrote upstairs can provide information or references that benefit friends who want to calibrate gas detectors. Thank you.